If you’ve ever wondered what all those wires are in an electric car, they are an old-school BMS or Battery Management System. The high-voltage orange cables are easily spotted but there are miles of wiring that monitor and communicate with the various components that make up a battery-powered propulsion system.

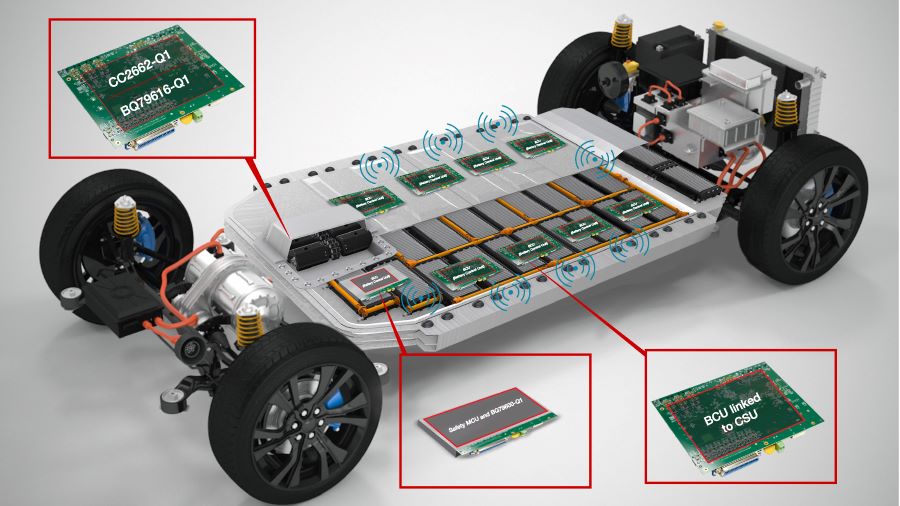

Current BMSs rely on physical wiring to connect each node to monitor system status. In the case of an electric vehicle battery, which typically contains more than 100 nodes, this can require yards of wiring to connect everything.

Despite these challenges, wired BMS remains the dominant approach for implementing battery management systems today. However, the wires can add a significant dollop of weight and occupy valuable real estate in the chassis that could otherwise be utilized for additional battery cells or features.

An analogy would be an old-school LAN that hardwires many computers (nodes) together to communicate. Wireless WiFi networks made all of the above (except in certain applications,) obsolete.

LG Innotek, a South Korean electronics company, has developed an 800v wireless Battery Management System (BMS) for electric vehicles, which is embedded with a Radio Frequency (RF) communication module. A BMS is an essential component that monitors the voltage, current, temperature, and other factors of a battery to optimize its performance and life span. Unlike traditional wired BMSs, the wireless BMS reduces the weight and volume of a battery pack. This volley by LG into the wireless BMS market has created quite a buzz.

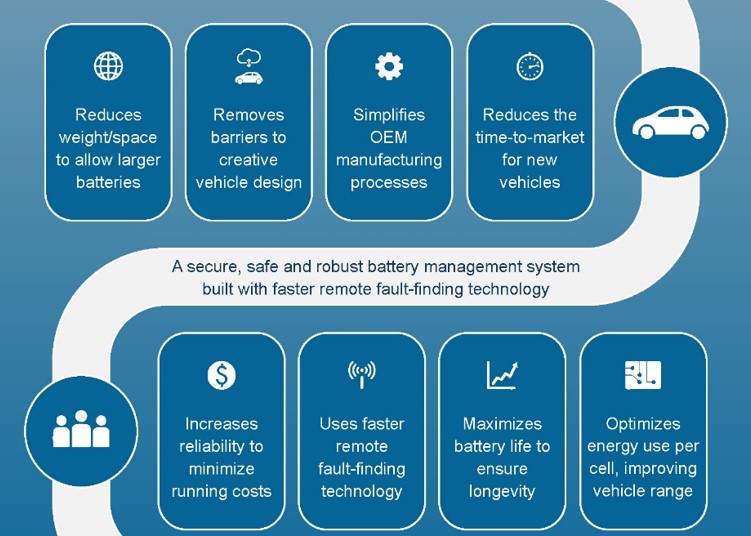

The key advantage of a wireless BMS is that it reduces the mass of an EV, and when the cables are removed, total vehicle weight is reduced by up to 200 lbs, which leads to additional space of 10-15% for a battery pack. This allows the battery’s capacity to be increased, improving the flexibility of vehicle packaging. A wireless BMS can increase the mileage of an electric vehicle by up to 12 miles as well.

The adoption of a wireless BMS improves the reliability of an electric vehicle and allows for the automated assembly of a battery pack, which cuts more costs. LG Innotek’s new system employs 800V, which is the highest voltage among commercially marketed BMSs, and the RF modules are compatible with all types of communication chips. This compatibility makes it easy for automobile manufacturers to integrate LG Innotek’s Wireless BMS in their electric vehicles.

LG Innotek plans to start mass production of its wireless BMS in 2024, and it expects major global automobile manufacturers to adopt this technology from 2024 onwards. The global market for wireless BMS’, which was only USD 7.16 million in 2022, is expected to grow to USD 1.1 billion in 2028. LG Innotek aims to expand its global foothold as a total solution provider and release next-generation automotive electrical components that provide differentiated customer value.

ElectrifiedMag’s Take: In an era of wireless communication it seems amazing that many EVs are still relying on miles of cabling to talk to various battery subsystems. The big drawback here is the ability to hack the system and bulletproof security will be paramount. Although Innotek claims that their new BMS will be available to all automakers, we think that it will show up in General Motors Ultium platform first.

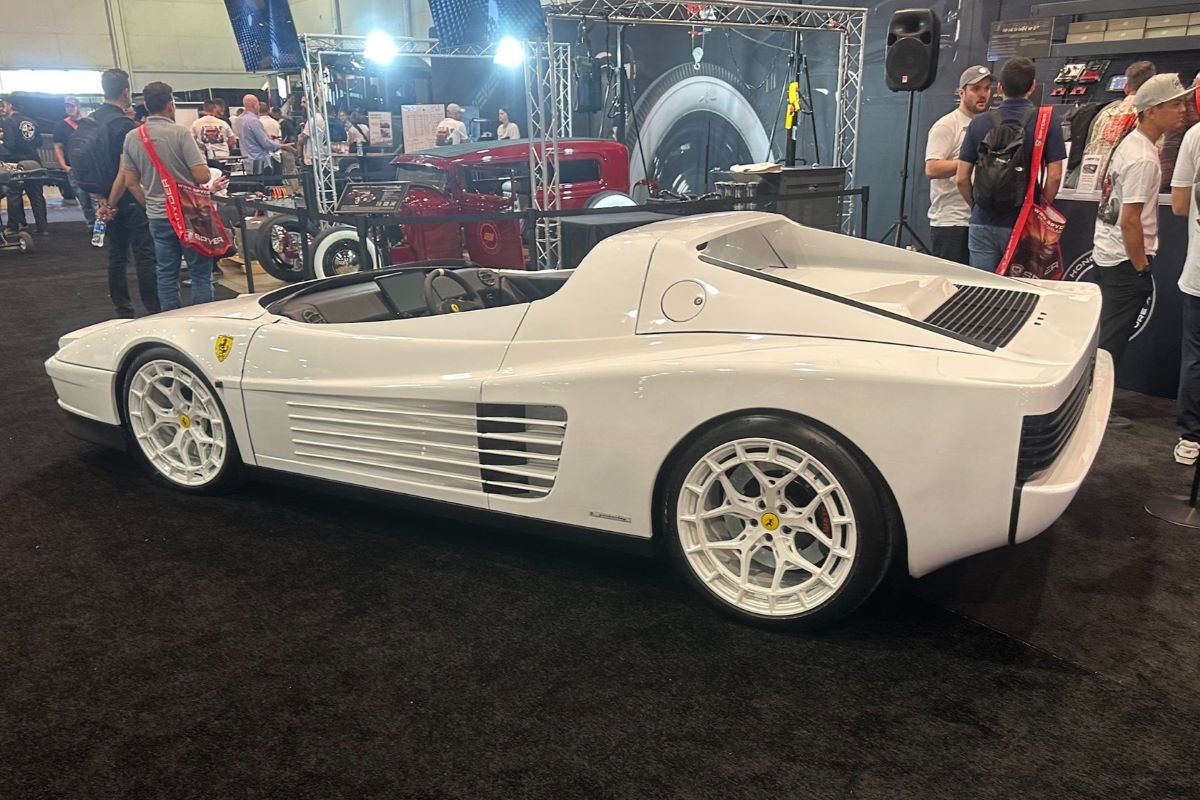

Although Ultium currently uses a wireless BMS sourced from Visteon, GM’s three battery factories with LG Chem offer obvious synergy and add to the General’s goal of verticle integration in its EV production. Even though industry rumors hint the two manufacturing titans have hit a rough patch, we think that the marriage of LG Chem and GM is now more valuable than ever, even if Ultium’s pouch-style batteries have raised some eyebrows.

If GM can quickly integrate the new BMS system into Ultium, it will give them a new way to cut costs and complexity inhouse and up the ante with Tesla (and all the other OEMs) in finding ways to reduce complexity, manufacturing costs, and ultimately the MSRP of new EVs.